Sewage Treatment

HL-CONT COMPACT SEWAGE TREATMENT PLANTS

Small and light wastewater treatment systems for superyachts, commercial and naval vessels and offshore installations

๐ The smallest and lightest sewage treatment plant on the market

๐ Cost optimized, short lead times

๐ Small package – big performance

๐ Certified to IMO res. MEPC.227 (64), USCG and EU MED

HL-CONT PLUS SEWAGE TREATMENT PLANTS

Versatile and powerful wastewater treatment systems for superyachts, ferries, cruise ships, commercial and naval vessels and offshore installations

๐ The most versatile sewage treatment plants

๐ Full customization options

๐ Simple installation on board

๐ Dismountable sewage treatment plants for easy retrofitting

๐ Certified to IMO res. MEPC.227 (64), USCG and EU MED

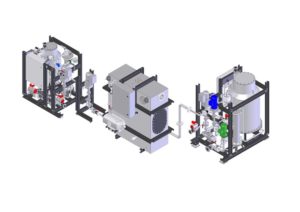

HL-CONT PLUS OCEANCRUISE ADVANCED WASTEWATER PURIFICATION (AWP) SYSTEMS

Advanced wastewater purification (AWP) systems for ferries and cruise ships operating in Alaskan waters or the Baltic sea

๐ Modular design for flexible installation and small footprint

๐ Low maintenance & ultimate reliability

๐ Certified to IMO res. MEPC.227 (64) incl. Section 4.2 (MARPOL special areas) and EU MED

๐ Compliant with US CFR Title 33 Part 159 Subpart E (Alaska)

HL-CONT PLUS RIVERCRUISE ADVANCED WASTEWATER PURIFICATION (AWP) SYSTEMS

Advanced wastewater purification (AWP) systems for river cruise ships and other inland navigation vessels

๐ Modular design for flexible installation and small footprint

๐ Low maintenance & ultimate reliability

๐ Certified to Commission Directive 2012/49/EU

PREVIOUS GENERATION SEWAGE TREATMENT PLANTS CERTIFIED TO IMO MEPC.159(55) OR IMO MEPC.2(IV)

We have been designing and manufacturing wastewater treatment systems since 1972. Technology has evolved and so has regulation. These older generation sewage treatment plants are no longer compliant with current regulations on sewage discharge.

HL-CONT PLUS 159(55) WASTEWATER TREATMENT PLANTS

๐ Certified to IMO res. MEPC.159(55)

๐ Current successor models: HL-CONT Plus

SUPER MINI PLUS WASTEWATER TREATMENT PLANTS

๐ Certified to IMO res. MEPC.159(55)

๐ Current successor models: HL-CONT Compact 0125, HL-CONT Plus 0125

HL-CONT PLUS 02 SLIM WASTEWATER TREATMENT PLANTS

๐ Certified to IMO res. MEPC.159(55)

๐ Current successor model: HL-CONT Plus 025

HL-CONT WASTEWATER TREATMENT PLANTS

๐ Certified to IMO res. MEPC.2(VI)

SUPER MINI IMO MEPC.2 CERTIFIED WASTEWATER PLANTS

๐ Certified to IMO res. MEPC.2(VI)

๐ Current successor models certified to IMO res. MEPC.227(64): HL-CONT Compact 0125, HL-CONT Plus 0125

GREASE SEPARATORS FOR WASTEWATER MANAGEMENT SYSTEMS

Grease separators are crucial for wastewater management systems. Grease has some properties that have a negative impact on the performance of the wastewater system. Pipelines and sensors are blocked or sealed by grease deposits within a short time. In holding tanks, grease accelerates the formation of hydrogen sulphide, a toxic and highly odorous gas. Hydrogen sulphide can lead to the formation of sulphuric acid, which then attacks the substance in the pipes. In addition, the purification performance of the wastewater treatment plant is severely impaired. Therefore, grease separators are crucial for wastewater management systems

Fat and oil mainly get into the waste water via food residues. Therefore, all waste water from kitchen areas, i.e. from sinks and dishwashers, should first pass through a grease separator before it is discharged into a holding tank. Food waste itself must always be treated separately from waste water. They fall under MARPOL Annex V. This also includes residual water from food waste treatment systems.

BENEFITS OF HAMANN GREASE SEPARATORS FOR WASTEWATER MANAGEMENT SYSTEMS

๐ Stainless steel design for maximum robustness

๐ Function after gravity separation

๐ No moving parts

๐ TÜV Rheinland certified according to DIN EN 1825-1, DIN EN 1825-2 and DIN EN 4040

HAMANN grease separators work exclusively according to the principle of gravity separation without mechanical parts or additives. Solid food residues are first separated from the waste water by gravity. Then, the fats and oils, which are lighter than water are collected at the top of the separation chamber of the grease separator. From there the collected fats and oils can be drained. A built-in heater keeps the fat liquid so that it can be drained more easily. Separated fats and oils from the grease separator, as well as solid food residues are transfered into external containers via the outlets provided for this purpose and disposed of ashore.

HAMANN grease separators are completely made of stainless steel. This makes HAMANN grease separators extremely robust and reliable.

HAMANN grease separators are the only DIN-certified grease separators for use in the maritime industry. HAMANN grease separators are certified by TÜV Rheinland according to DIN EN 1825-1, DIN EN 1825-2 and DIN EN 4040.